Unlock 5–8% More Energy: Why N-type TOPCon is the Smart Choice for Commercial Solar

Posted by SLD Tech Inc on 31st Oct 2025

In the world of commercial solar, every decision impacts the bottom line. For engineers, procurement managers, and asset owners, the choice of photovoltaic (PV) technology is no longer just about upfront cost—it's about maximizing lifetime value and securing a predictable return on investment (ROI).

This is where N-type TOPCon (Tunnel Oxide Passivated Contact) solar panels have become a game-changer. They represent a critical strategic advantage, delivering 5–8% greater lifetime energy yield compared to older P-type PERC technologies. This isn't a minor update; it’s a fundamental shift that protects and enhances your project's financial performance over its entire 25–30 year lifespan.

The Core Advantage: Why N-type Silicon Outperforms P-type

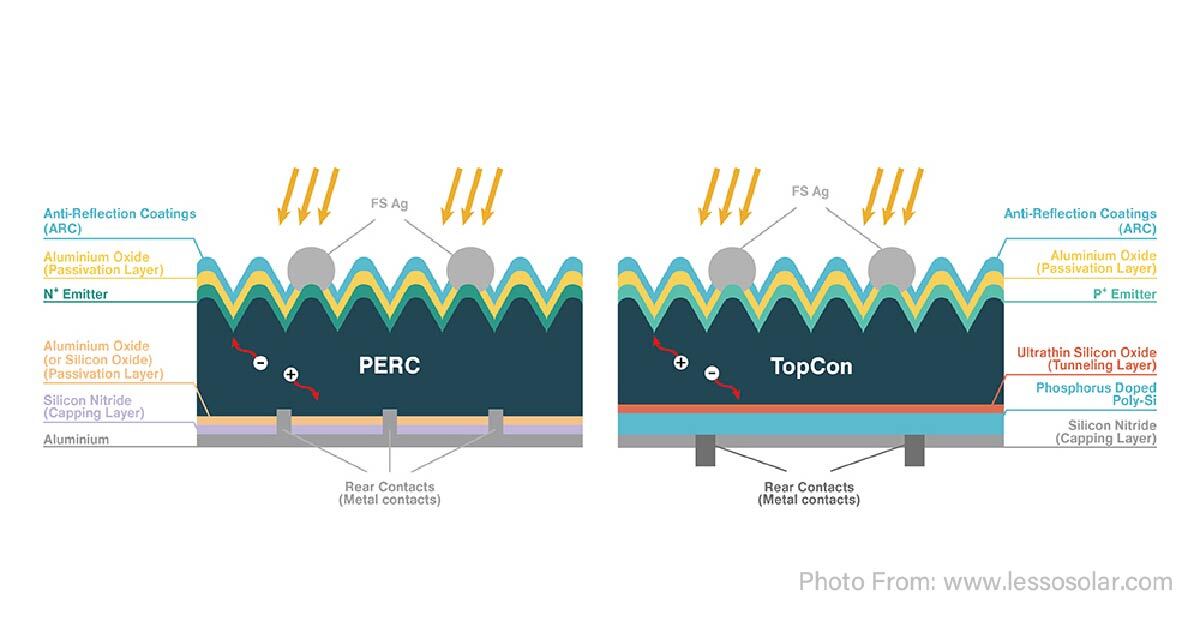

To understand the superior yield of TOPCon, we need to look at the foundational material. Traditional panels (P-type PERC) use boron-doped silicon, which has an inherent flaw. TOPCon technology uses phosphorus-doped N-type silicon, which is fundamentally more stable and efficient.

This difference delivers two immediate benefits that secure your performance from day one:

Elimination of Light-Induced Degradation (LID): P-type cells suffer from boron-oxygen defects that cause an initial energy loss of 1–2% right after installation. N-type silicon is virtually immune to this, ensuring your system performs at its rated capacity from day one.

Superior Electron Mobility: N-type silicon allows electrons to move more freely, resulting in consistently higher energy conversion efficiency (typically 22–24% vs. 21–22% for PERC).

How TOPCon Technology Maximizes Your Energy Harvest

The "TOPCon" architecture is what unlocks the full potential of the N-type wafer. It uses an ultra-thin tunnel oxide layer to minimize energy loss, directly translating into more power for your business.

1. Higher Initial Efficiency in a Smaller Footprint

TOPCon modules achieve higher initial conversion efficiencies, outperforming PERC by 1–2% absolute efficiency. For space-constrained commercial rooftops or land-limited sites, this means you generate more power from the same area. It’s a direct boost to your project's megawatt-hours per square meter, making your investment immediately more productive.

2. Superior Performance in Real-World Heat

Heat is the silent enemy of solar efficiency. As temperatures rise, panel performance drops. TOPCon panels are simply better at handling the heat.

PERC Temperature Coefficient: Typically around –0.35%/°C

TOPCon Temperature Coefficient: Typically around –0.30%/°C

This 0.05% difference means that on a hot day, a TOPCon array will lose significantly less power than a PERC array. Over thousands of hot days each year, this advantage compounds, contributing significantly to the 5–8% lifetime yield gain.

The Financial Impact: Lower Degradation and 30-Year Security

For any B2B investment, long-term reliability and Total Cost of Ownership (TCO) are paramount. TOPCon technology is built to excel in both areas, protecting your asset value for decades.

3. Dramatically Slower Degradation Rates

The stability of N-type silicon results in a much lower annual degradation rate. This is the single biggest factor in long-term energy production and asset management.

Conventional P-type Degradation: 0.55% per year

N-type TOPCon Degradation: 0.4% per year

While this looks small on paper, the impact is massive. After 25 years, a TOPCon system will have retained significantly more of its original power output, ensuring a more predictable and profitable revenue stream.

4. Enhanced Bankability with 30-Year Warranties

Reflecting this proven durability, leading manufacturers now confidently offer 30-year linear performance warranties on TOPCon products. This extended assurance is crucial for commercial projects with long investment horizons. It reduces risk for asset owners and makes it easier to secure project financing, enhancing the overall "bankability" of your investment.

The combination of higher initial output, better heat performance, and slower degradation is precisely how TOPCon technology delivers that 5–8% greater lifetime energy yield. For a multi-megawatt commercial system, this equates to thousands of extra megawatt-hours over the project life—directly translating to superior project economics and a stronger ROI.

Procurement & Implementation Checklist for TOPCon

When specifying TOPCon for your next commercial solar project, use this checklist to ensure a successful deployment:

System Compatibility: Confirm TOPCon modules are fully compatible with your chosen inverters, racking, and monitoring systems. (They are, but it's good practice to verify).

Certification & Compliance: Ensure panels meet all required standards, including IEC 61215, IEC 61730, and UL 61730, for safety and performance in North America.

Supplier Expertise: Partner with a manufacturer that demonstrates deep technical expertise, robust quality control, and a stable supply chain. This ensures you get the performance you pay for and the support you need.

Conclusion: Future-Proof Your Commercial Solar Investment

For commercial and industrial solar projects, the shift to N-type TOPCon is a strategic imperative. It moves the conversation from simple cost-per-watt to long-term value-per-watt. By leveraging TOPCon's technical superiority, you are not just buying a panel; you are securing a more efficient, more stable, and more profitable energy asset for the next three decades.

Reference Sources

International Technology Roadmap for Photovoltaic (ITRPV). (2023). "Trends in Cell Technology and Manufacturing."

Fraunhofer Institute for Solar Energy Systems. (2022). "Photovoltaics Report: Evaluation of N-type versus P-type Silicon Solar Cells."

National Renewable Energy Laboratory (NREL). (2023). "Technical Assessment of TOPCon Solar Cell Technology for Commercial Applications."

Jinko Solar. (2023). "White Paper: TOPCon Technology and Performance Validation."

Solar Power World. (2023). "The Evolution of Solar Cell Technology: From PERC to TOPCon."

Underwriters Laboratories. (2022). "UL 61730: Standard for Safety for Photovoltaic (PV) Modules."

International Electrotechnical Commission. (2023). "IEC 61215: Terrestrial photovoltaic (PV) modules - Design qualification and type approval."