The Solar Supply Chain Uncovered: A Tier-1 Partner's 3-Stage Quality Control Process

Posted by SLD Tech Inc on 25th Dec 2025

In commercial solar, the lowest price-per-watt is a tempting but often misleading metric. The true cost of a solar project is measured in long-term reliability, performance guarantees, and the financial stability of your supply chain. A single flawed module or a compromised batch can cascade into significant O&M costs and erode a project's ROI over its 25-year lifespan.

For developers, asset owners, and procurement managers, this makes supplier transparency non-negotiable. At ACULTRA, we believe the manufacturing journey isn't just an assembly line; it's a series of critical quality gates designed to eliminate risk and protect your investment.

This is the transparent journey your solar panels take, from initial concept to sealed container, showcasing the rigorous standards that define a true Tier-1 partnership.

Gate 1: Engineering & Material Sourcing (The Foundation)

Quality isn't inspected into a product; it's designed in. Our QC process begins long before production, in the critical phase of engineering and supplier selection.

Application-Specific Engineering: We specialize in custom non-standard PV modules, moving beyond one-size-fits-all solutions. Our engineering team designs for specific power, size, shape, and installation requirements. This ensures the panel is perfectly engineered for its application—optimizing performance from day one.

Tier-1 Material Vetting: A panel is only as strong as its components. We commit to using first-tier brand materials for foundational stability. Our QC team rigorously vets every input, from the A-grade monocrystalline cells to the precise thickness of the tempered glass, ensuring consistent quality across every batch.

Compliance by Design: Our processes are built to exceed global standards. We hold full product certification from TÜV SÜD, covering IEC 61215 (performance) and IEC 61730 (safety), alongside ISO certifications for quality and environmental management. This isn't just a final check; it's the blueprint for our entire operation.

Gate 2: Automated Manufacturing & In-Line Testing (The Production Line)

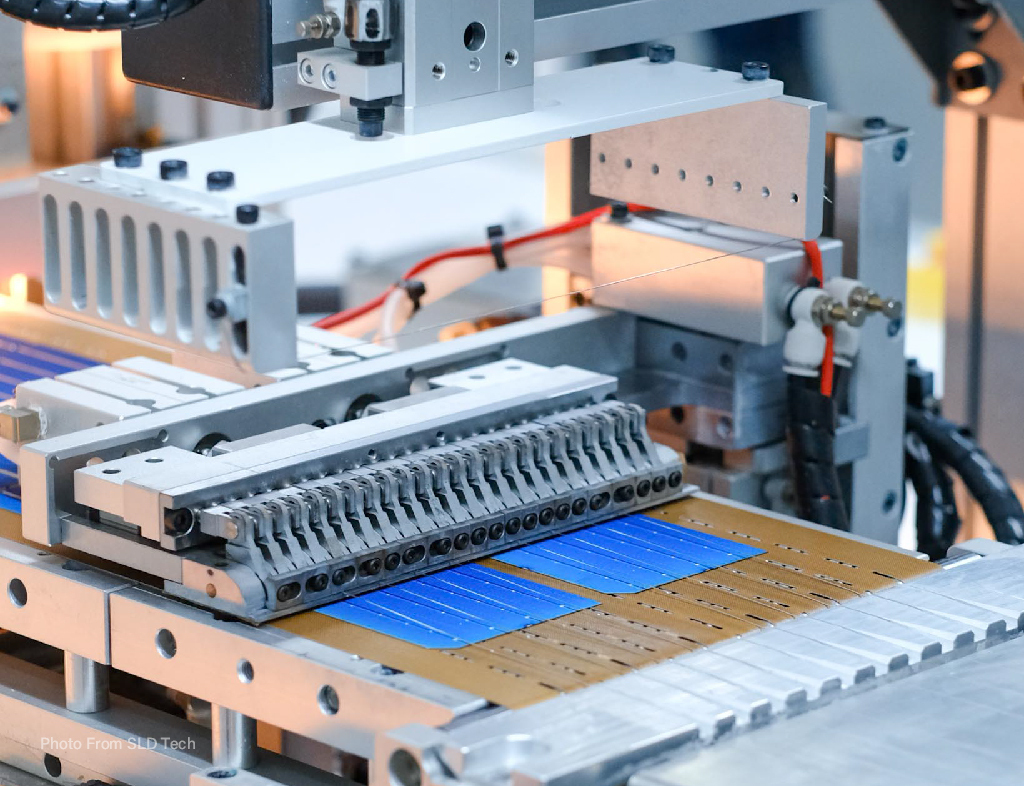

In our nearly 10,000 square meter, highly automated production base, precision is paramount. Automation eliminates human error and ensures every panel is identical to the last.

Automated Precision: Our advanced intelligent production lines are the core of our quality consistency. This automation not only guarantees uniformity but also accelerates our ability to scale new, custom solutions with proven reliability.

Microscopic Defect Detection: The most dangerous defects are invisible to the naked eye. Every panel undergoes Electroluminescence (EL) testing—acting like an X-ray—to reveal micro-cracks, soldering faults, or cell defects that could lead to premature failure. We pair this with real-time I-V curve testing to verify electrical performance immediately.

Durability Sealing: The lamination process is the panel's primary defense against the elements. Our QC ensures the encapsulant and backsheet are perfectly sealed to prevent moisture intrusion and Potential Induced Degradation (PID), directly securing the panel's 25-year longevity.

Gate 3: Final Validation & Logistics (The Shipment)

The final gate ensures the panel that leaves our factory is the one that performs on your roof, protected for its journey and ready for decades of service.

Certified Power Output: Every single module receives a final power flash test to confirm its output (Pmax) meets or exceeds its nameplate rating. Our TÜV certification includes full power coverage, giving you third-party validation that the power you paid for is the power you get.

Structural & Environmental Integrity: We conduct final mechanical checks on the aluminum alloy frame and junction box, verifying waterproof ratings and structural strength. This is especially vital for our specialized series (like the Ultra Slim and NanoEdge) engineered for high-stress applications.

Secure Logistics: Quality extends to the final mile. We use durable, engineered packaging designed to withstand the rigors of global shipping, ensuring the module you approved is the module you receive, in perfect condition.

Beyond the Panel: The B2B Strategic Partnership Advantage

For B2B clients, choosing a supplier is a long-term strategic decision. As a source factory with over two decades of dedicated experience in PV application technologies, ACULTRA offers more than just a product. We provide a partnership built on transparency, deep technical expertise, and a competitive cost structure.

Our commitment is to help you reduce production risks, enhance your project's bankability, and improve your end-customer's profitability.

Ready to de-risk your supply chain and partner with a transparent Tier-1 manufacturer? Contact our B2B team today for a customized quote and a technical consultation.

Reference Sources

International Technology Roadmap for Photovoltaic (ITRPV). (2023). "Trends in Cell Technology and Manufacturing."

Fraunhofer Institute for Solar Energy Systems. (2022). "Photovoltaics Report: Evaluation of N-type versus P-type Silicon Solar Cells."

National Renewable Energy Laboratory (NREL). (2023). "Technical Assessment of TOPCon Solar Cell Technology for Commercial Applications."

Jinko Solar. (2023). "White Paper: TOPCon Technology and Performance Validation."

Solar Power World. (2023). "The Evolution of Solar Cell Technology: From PERC to TOPCon."

Underwriters Laboratories. (2022). "UL 61730: Standard for Safety for Photovoltaic (PV) Modules."

International Electrotechnical Commission. (2023). "IEC 61215: Terrestrial photovoltaic (PV) modules - Design qualification and type approval."