The Engineering Behind High-Efficiency Monocrystalline Modules: A Deep Dive into SLED Tech’s 10BB Technology

Posted by SLD Tech Inc on 16th Dec 2025

Understood. To reach the 1000+ word mark for high-level B2B SEO, we need to dive deep into the specific engineering challenges, the "Levelized Cost of Energy" (LCOE) mathematics, and the granular technical differences that matter to an EPC (Engineering, Procurement, and Construction) contractor.

Here is the expanded, comprehensive version of Blog 1.

The Engineering Behind High-Efficiency Monocrystalline Modules: A Deep Dive into SLED Tech’s 10BB Technology

Introduction: The New Standard in Industrial Power

In the global shift toward renewable infrastructure, the "one-size-fits-all" approach to solar procurement is rapidly becoming obsolete. For industrial operators, telecommunications firms, and remote facility managers, a solar panel is far more than a silicon wafer in a frame—it is a critical component of a 25-year financial and operational strategy.

At SLD Tech, we recognize that industrial environments demand a higher caliber of engineering. This is why we have centered our R&D on 10BB (10 Busbar) Monocrystalline technology. This deep dive explores the physics, the manufacturing precision, and the long-term economic advantages of 10BB technology, and why it is the superior choice for industrial solar modules in 2026.

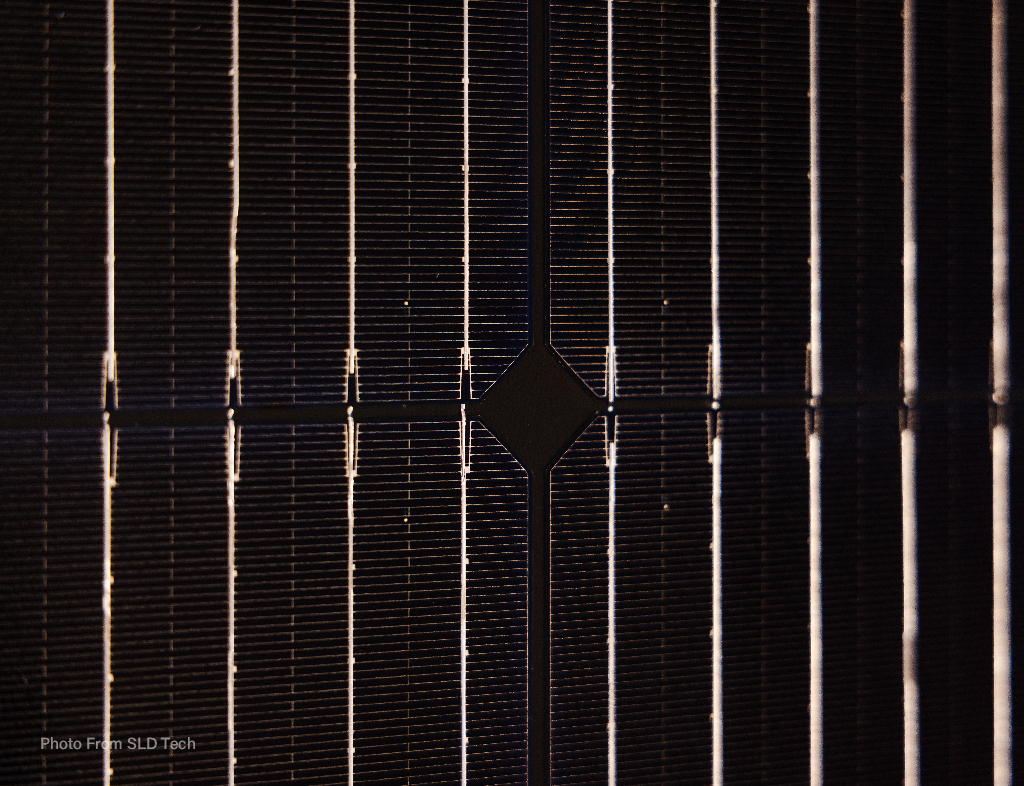

1. The Physics of the Busbar: Why "10" is the Magic Number

To understand why 10BB matters, we must first understand the fundamental role of the busbar. In a solar cell, busbars are the silver or copper "highways" that collect the current generated by the silicon and transport it to the junction box.

The Problem with Traditional 5BB Systems

In older 5BB (5 Busbar) designs, the distance between each busbar was relatively wide. Electrons generated in the silicon had to travel a significant distance across the cell surface to reach a collector. In physics, Distance = Resistance. The longer the path, the more energy is lost as heat before it even leaves the cell.

The 10BB Advantage: Reducing the "Mean Path"

By moving to a 10BB architecture, SLD Tech effectively halves the distance electrons travel. This architectural shift results in three critical technical advantages:

-

Lower Internal Resistive Losses: By increasing the number of collection points, we reduce the "series resistance" of the cell. This directly translates into higher wattage output from the same surface area.

-

Increased Sunlight Absorption: While it may seem counterintuitive that adding more silver lines increases efficiency, modern 10BB wires are "circular" or "triangular" in cross-section rather than flat. This allows sunlight to reflect off the wire and back into the silicon rather than being shaded.

-

Uniform Stress Distribution: During thermal expansion (day/night cycles), solar cells physically expand and contract. Ten busbars distribute this physical stress more evenly across the wafer, preventing the cell from bowing or cracking over time.

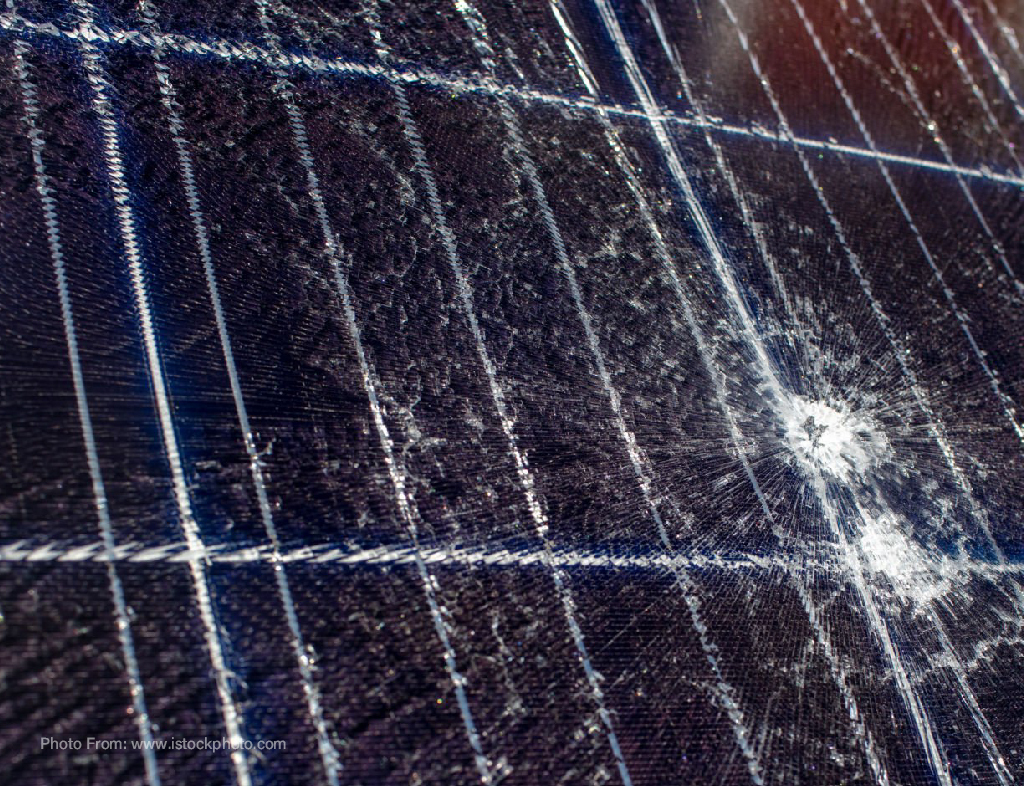

2. Mitigating the "Hidden Killer": Micro-cracks and Durability

In the world of off-grid solar solutions, durability is not just a marketing term—it is a survival requirement. Remote sites are subject to heavy wind loads, snow pressure, and the constant vibrations of nearby industrial machinery.

Why Micro-cracks Happen

Micro-cracks are microscopic fractures in the silicon that are invisible to the naked eye but catastrophic to power output. In a standard 5BB cell, a single micro-crack can "isolate" a large chunk of the cell, effectively killing its ability to contribute power.

The 10BB Safety Net

With 10BB technology, the paths for electricity are so dense that even if a micro-crack occurs, the current can almost always find an alternative path to a busbar. Think of it like a city grid: if one road is blocked in a 5-road town, traffic stops. If one road is blocked in a 10-road city, there are multiple detours. This makes SLED Tech industrial solar modules significantly more resilient to the physical rigors of long-term deployment.

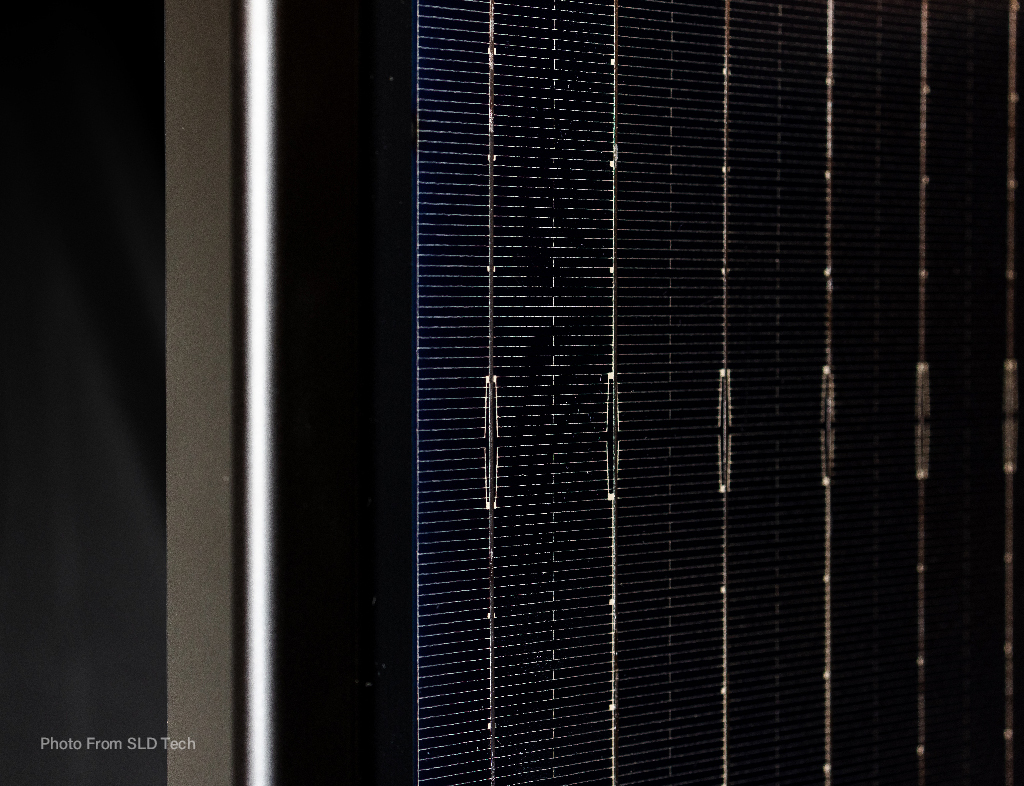

3. Monocrystalline Purity: The Foundation of B2B Efficiency

While the busbar is the highway, the silicon is the fuel. SLED Tech exclusively utilizes high-purity N-Type Monocrystalline silicon.

Monocrystalline vs. Polycrystalline: The B2B Verdict

Polycrystalline panels consist of multiple crystal fragments melted together, creating "grain boundaries" that act as barriers to electron flow. Monocrystalline wafers are sliced from a single, continuous crystal lattice.

-

Energy Density: Our monocrystalline modules achieve efficiencies between 21.5% and 23.0%, whereas industrial polycrystalline rarely exceeds 17%.

-

Temperature Coefficient: Industrial sites often face extreme heat. Standard panels lose significant power as they get hot. SLD Tech’s modules feature a superior temperature coefficient (approx. -0.35%/°C), meaning they produce more power in the desert than a standard competitor.

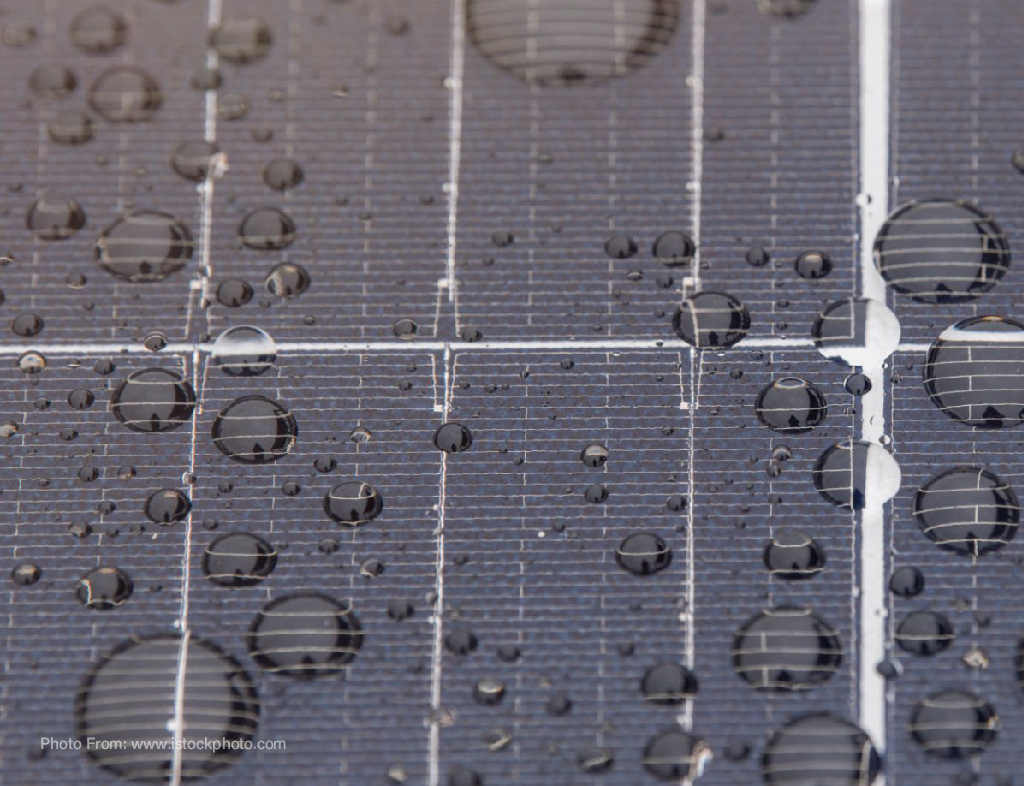

4. Low-Light Performance: Powering the "Marginal Hours"

For High-efficiency solar modules, the real test isn't high noon; it’s 6:30 AM on a rainy Tuesday. In B2B applications, such as telecommunications or security infrastructure, the system must stay alive during "marginal" light conditions.

Our 10BB cells utilize PERC (Passivated Emitter and Rear Cell) technology. We add a specialized layer to the back of the cell that reflects light back into the silicon for a "second chance" at absorption. This increases the voltage during low-light hours, ensuring your MPPT (Maximum Power Point Tracking) controllers wake up earlier and stay active longer than the competition.

5. Industrial Build Quality: Beyond the Silicon

An industrial panel is only as strong as its weakest component. SLED Tech’s manufacturing process focuses on the "Bill of Materials" (BOM) that survives the elements:

-

3.2mm Tempered Glass: Low-iron, high-transparency glass designed to resist 1-inch hail at 50 mph.

-

Anodized Aluminum Frames: Reinforced frames that can handle snow loads up to 5400 Pa and wind loads up to 2400 Pa.

-

IP68 Junction Boxes: Fully potted and sealed against moisture, preventing the "PID" (Potential Induced Degradation) that plagues cheaper modules in humid coastal environments.

6. The Economic Reality: ROI and LCOE for 2026

In 2026, savvy procurement managers are moving away from the "Price per Watt" metric and toward Levelized Cost of Energy (LCOE).

Why SLED Tech Wins the LCOE Battle

If you buy a cheap panel for $100 that lasts 10 years, your cost of energy is high. If you buy a SLED Tech panel for $140 that lasts 25 years with a linear degradation rate of only 0.5% per year, your total cost per kilowatt-hour is drastically lower.

-

Reduced BOS Costs: Because our panels are more efficient, you need fewer rails, fewer cables, and fewer man-hours for installation to reach your target wattage.

-

O&M Savings: High-durability 10BB panels require fewer replacements and fewer site visits for troubleshooting, which is the single largest expense in remote industrial power infrastructure.

7. Strategic Outlook: Scaling with SLED Tech

As we move toward a more electrified future, the reliability of the "Off-grid" grid depends on the quality of the modules. SLED Tech’s 10BB technology represents the pinnacle of current photovoltaic engineering. By choosing our modules, you are not just buying power; you are buying the peace of mind that comes with industrial-grade resilience.

Conclusion: Partnering for Performance

The transition to High-efficiency solar modules is an investment in your company’s operational future. Whether you are an EPC contractor designing a multi-megawatt array or a facility manager for a remote sensor network, SLED Tech provides the technical foundation you need to succeed.