Solar Supply Chain 2025: Challenges & Resilient Strategies

Posted by SLD Tech Inc on 29th Jun 2025

Introduction

The solar supply chain has never been more complex—or more critical. As demand for solar installations skyrockets, businesses face a host of challenges, from material shortages and logistics delays to regulatory hurdles and geopolitical risks. Yet, within these challenges lie significant opportunities for companies that can adapt and innovate. In this blog, we’ll examine the current state of the solar supply chain, identify key pain points, and explore strategies for building a more resilient and efficient procurement process.

1. The Global Solar Supply Chain Landscape

Solar energy is a global industry, with raw materials, components, and finished products flowing across multiple continents. The majority of solar panels are manufactured in Asia, particularly in China, which dominates the production of photovoltaic (PV) cells and modules. While this has driven down costs through economies of scale, it has also created vulnerabilities, including trade disputes, shipping delays, and quality control issues.

For businesses procuring solar equipment, understanding this global network is essential. SLD Tech has developed strong relationships with leading manufacturers and logistics partners, ensuring a steady supply of high-quality components even during periods of market disruption.

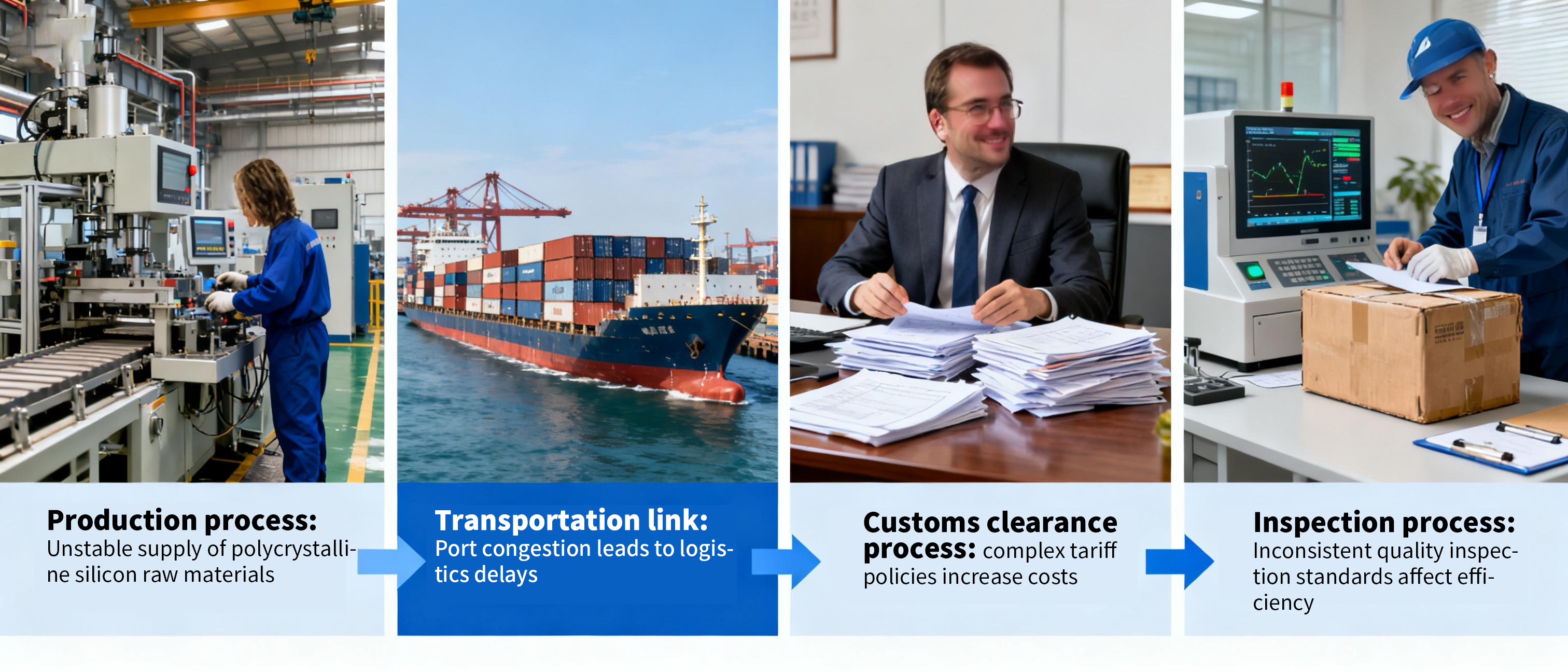

2. Key Challenges Facing the Industry

Material Shortages

The surge in solar demand has led to shortages of critical materials like polysilicon, aluminum, and copper. These shortages can delay project timelines and increase costs. Businesses must plan ahead and secure supply contracts early to mitigate these risks.

Shipping and Logistics

Global shipping constraints, port congestion, and rising freight costs have impacted the delivery of solar equipment. Long lead times require careful project scheduling and inventory management.

Regulatory and Trade Barriers

Tariffs, import restrictions, and local content requirements vary by country and can change rapidly. Navigating this regulatory landscape requires expertise and agility.

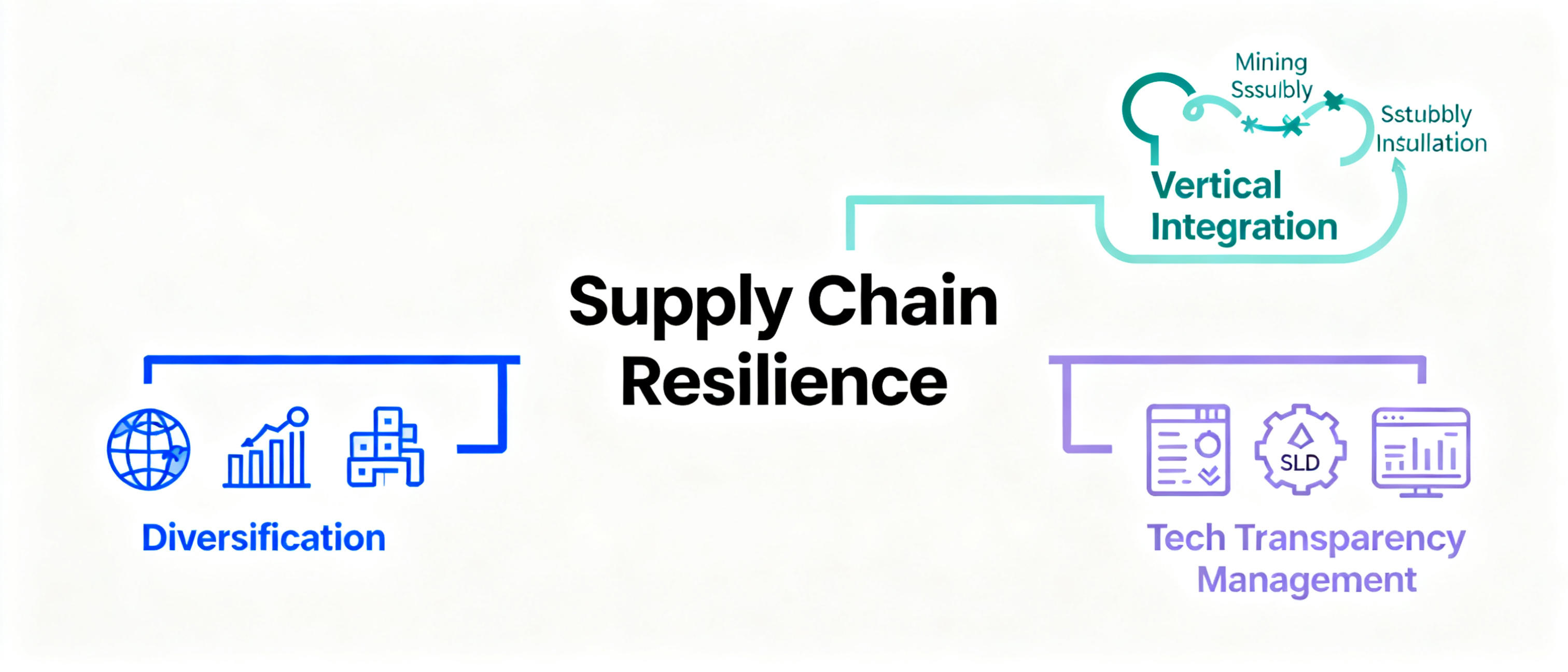

3. Strategies for Supply Chain Resilience

To thrive in this environment, businesses must adopt proactive supply chain strategies:

Diversification

Relying on a single supplier or region is risky. Diversifying suppliers across geographies and technologies can reduce dependency and increase flexibility.

Vertical Integration

Some companies are bringing more of the supply chain in-house, from raw material sourcing to module assembly. This approach provides greater control over quality and timing.

Technology and Transparency

Advanced software platforms now offer real-time visibility into supply chain operations, enabling better decision-making and risk management. SLD Tech utilizes digital tools to track orders, monitor inventory, and forecast demand, ensuring smooth project execution.

4. The Role of Local Manufacturing and Nearshoring

In response to global disruptions, there’s a growing movement toward localizing solar manufacturing. Governments are incentivizing domestic production through subsidies and policy support. Nearshoring—sourcing from nearby countries rather than distant ones—can also reduce shipping times and costs.

For businesses, this means more options for sourcing solar equipment and potentially faster project completion. SLD Tech is actively monitoring these developments and adjusting its procurement strategies to take advantage of emerging local supply chains.