Customization as the New Standard: Tailoring Solar Panels for Niche Industrial and OEM Applications

Posted by SLD Tech Inc on 31st Dec 2025

Introduction

If you are a product designer, an engineer, or work for an OEM manufacturer, you know a simple truth. The best product is a product that fits perfectly. In the worlds of recreational vehicles (RV), marine technology, and telecommunications, one size does not fit all. This is especially true for solar panels. For a long time, many people believed that solar power was only for rooftops or large fields. They thought you could only choose from a few standard sizes and powers.

But this way of thinking is a problem. It forces you to design your product around the solar panel, not the other way around. An off-the-shelf, standard panel often creates problems. It might be the wrong shape, the wrong size, or not strong enough for the environment. This means you have to compromise your design. And compromise can lead to product failure.

This blog will explain why custom solar panels are no longer a luxury. For specialized “industrial applications”, they are a necessity. We will show how custom manufacturing is the new standard for successful “niche integration”. It is the key to creating better, more reliable, and more powerful products.

The Limits of Off-the-Shelf Panels

Standard solar panels are made for one main purpose: to sit on a roof. They are designed to be big and efficient for a home or business. But what happens when you try to use them in a special situation? You face many challenges.

First, the “size and shape”are often wrong. The space on the roof of an RV or a boat is not a perfect rectangle. There are vents, antennas, and curved surfaces. A standard rectangular panel does not use the available space well. This means you lose potential energy.

Second, the “power output” may not be correct. Maybe your telecommunications device needs a very specific voltage. Or your portable medical device needs a small but very steady power supply. A standard panel’s electrical characteristics might not be perfect for this.

Third, standard panels are often not strong enough for “special environments”. The marine environment has salt water and constant vibration. An RV travels on rough roads and faces different weather. A standard glass panel can be too heavy and too fragile for these conditions.

When you use a standard panel, you are forcing your design to accept these problems. This is not good engineering.

The Power of Custom Manufacturing for OEM

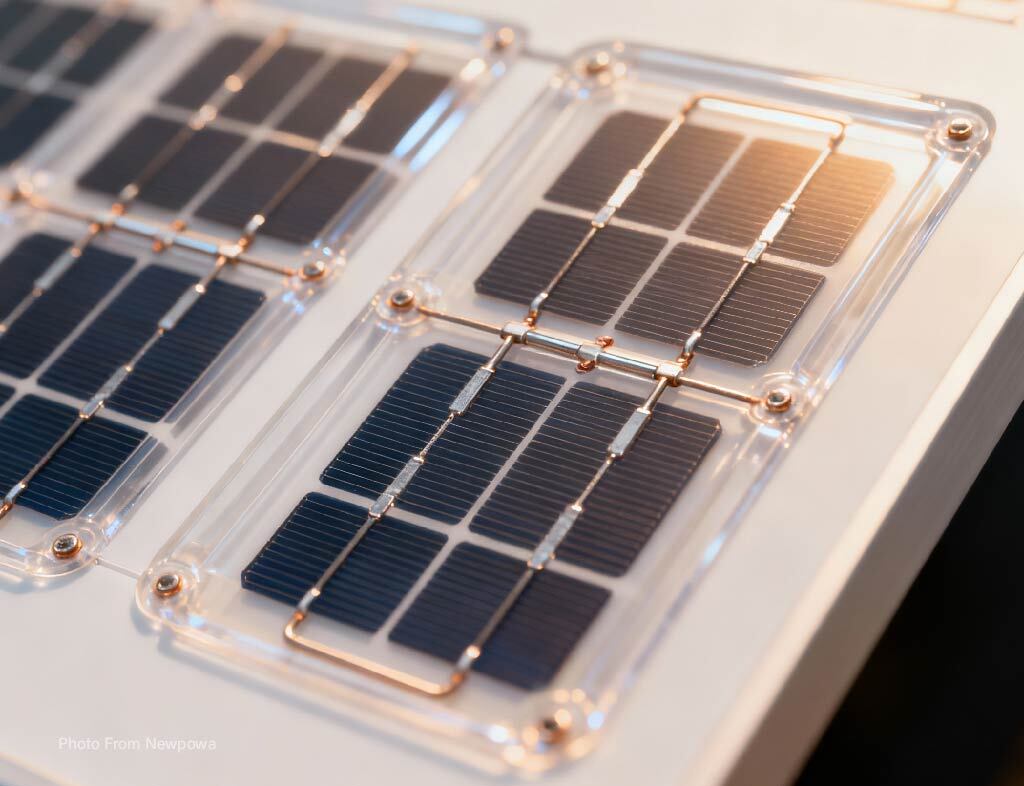

Custom manufacturing solves these problems. It allows you to think of the solar panel not as a separate part, but as a component integrated into your product. This is the core of successful “OEM ” collaboration. Let us look at the key areas you can customize.

- Physical Dimensions: Making the Panel Fit the Space

The most obvious advantage is physical customization. You are no longer limited to a rectangle. With modern manufacturing, we can create panels in different shapes and sizes.

Size: You can have very small panels for sensors or very large, thin panels for a bus roof.

Shape:This is very important. We can make panels that are not rectangles. For example, we can make a panel that fits around a satellite dish on a boat. Or we can make a long, thin panel to fit along the side of a truck trailer. This means you can use one hundred percent of the available space.

Flexibility: For curved surfaces like some boat roofs, a flexible panel is necessary. Custom manufacturing can create panels that can bend to a certain degree, allowing for perfect and strong integration.

- Electrical Characteristics: Matching the Power Need

The electrical output of a solar panel is also something we can change. This is a technical point that many people do not know.

Voltage and Current:We can design the internal cell arrangement to give you the exact voltage or current that your system needs. This means you can often remove extra electronics, making your product simpler and cheaper.

Power Output: You can specify the exact wattage you need. You do not have to choose between a 100W panel that is too weak and a 150W panel that is too big. We can make a 125W panel that fits your space and power requirements perfectly.

- Durability and Materials: Building for the Environment

Finally, we can change the materials and construction of the panel to survive in your product’s environment.

Marine Use: We can use special coatings that resist salt water corrosion. We can make the frame from stainless steel or even create a frameless panel for easier cleaning.

RV and Transport: We can use stronger, lighter materials and make sure the panel can handle the vibration from driving on a highway.

Extreme Temperatures: For desert or arctic use, we can use materials that will not crack or degrade.

Real-World Benefits for Your Business

Choosing custom solar panels is not just about solving technical problems. It is about making your business stronger and your products better.

Better Product Performance: A perfectly integrated panel provides more reliable power. This makes your final product – whether it is an RV, a boat, or a communication device – more valuable to the customer.

Improved Aesthetics: A custom panel looks like it was made for your product. It does not look like an afterthought. This improves the design and the customer's perception of quality.

Competitive Advantage: When your competitors are using standard panels and dealing with their limits, you are offering a superior, perfectly designed product. This can help you win more business.

Conclusion: Stop Adapting, Start Integrating

The old way of thinking was to adapt your design to a standard solar panel. This time is over. For modern “product designers”and “OEM manufacturers”, the new standard is to integrate a solar panel that is made for you.

Customization is not a special service for a few clients. It is a necessary part of the design process for specialized “industrial applications”. It is the difference between a product that works okay and a product that works perfectly.